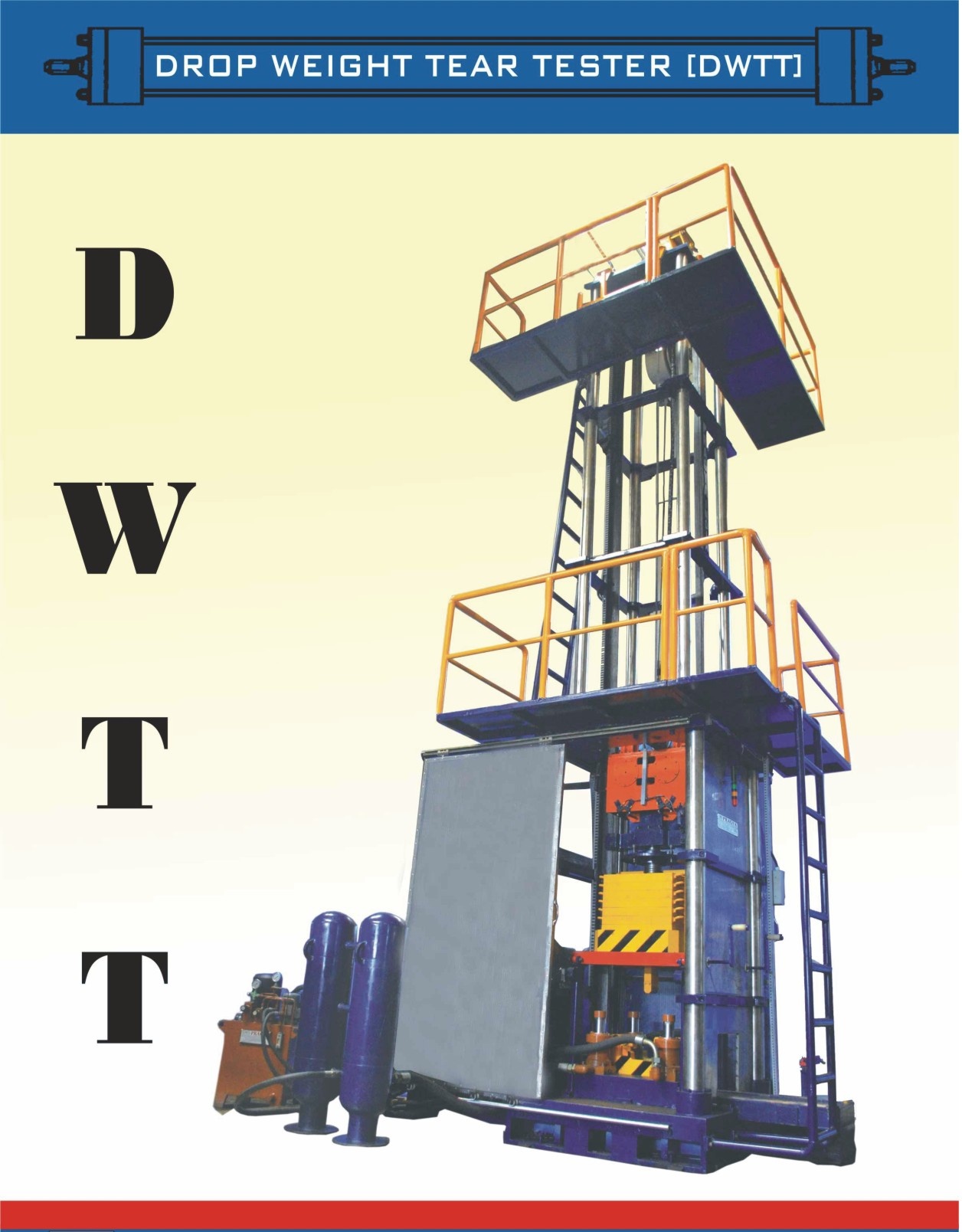

Drop Weight Tear Tester (DWTT)

Drop Weight Tear Tester (DWTT) - Specialized testing equipment for evaluating fracture characteristics of ferritic steels

DWTT Overview

Drop Weight Mechanism

Testing Operation

Control System

Side View

Schematic View

The Drop Weight Tear Tester (DWTT) evaluates fracture resistance in ferritic steels used for pipelines and pressure vessels. By subjecting notched specimens to controlled impact, it determines a material's resistance to brittle fracture propagation. Available in standard, high-capacity, and low-temperature configurations with impact energies from 20,000J to 100,000J.

Product Variants

- Standard DWTT: For routine drop weight tear testing operations

- High-Capacity DWTT: Enhanced impact energy for thicker materials

- Low-Temperature DWTT: Integrated cooling system for testing down to -100°C

Specifications

Impact Energy:

20,000J to 100,000J

Impact Velocity:

5 to 8 m/s

Specimen Size:

300 × 75 × 3-50 mm

Temperature Range:

-100°C to +20°C

Standards:

ASTM E436, API RP 5L3, EN 10274

Key Features

- Adjustable drop height for precise energy control

- Hardened hammer and anvil (HRC 56+)

- Integrated low-temperature cooling system

- Compliant with international testing standards

Applications

- Pipeline material qualification

- Pressure vessel material testing

- Steel plate fracture toughness evaluation

- Material certification testing